Moulds and toolmaking

After consultation with our customers, we manufacture tools from various steels and aluminium, from rapid tooling to series production tools.

The focus is on the requirements for the use of the tool and its intended purpose while taking into account the costs of the resulting parts.

Moulds and toolmaking

After consultation with our customers, we manufacture tools from various steels and aluminium, from rapid tooling to series production tools.

The focus is on the requirements for the use of the tool and its intended purpose while taking into account the costs of the resulting parts.

Injection moulds

Our mould and tool making department uses low-stress quality steel or aluminium for the production of injection moulds (prototypes and series production), depending on the requirements. The tools are and can also be manufactured cost-optimised with hand inserts. “Puzzle system solutions” are also possible.

Furthermore, mould plates are also produced individually for master moulds. Multiple cavities are possible. Samples incl. measurement reports, EMPBs are produced on different injection moulding machines in quantities from 1 to 50,000.

Gauges and jigmaking

For compliance with prescribed quality standards, we provide support with accurate measurement recordings and control and measurement gauges for component testing.

Close collaboration with our in-house quality control ensures a consistently high level in order to meet growing technological demands.

Gauges and jigmaking

For compliance with prescribed quality standards, we provide support with accurate measurement recordings and control and measurement gauges for component testing.

Close collaboration with our in-house quality control ensures a consistently high level in order to meet growing technological demands.

Your enquiry to us

Which of your ideas or sketches may we create for you in steel or aluminium?

We look forward to receiving your enquiry.

Your enquiry to us

Which of your ideas or sketches may we create for you in steel or aluminium?

We look forward to receiving your enquiry.

Contract manufacturing

All operations required for further processing or finishing, such as turning, milling, sawing, grinding and drilling, are carried out by the relevant departments of the company itself.

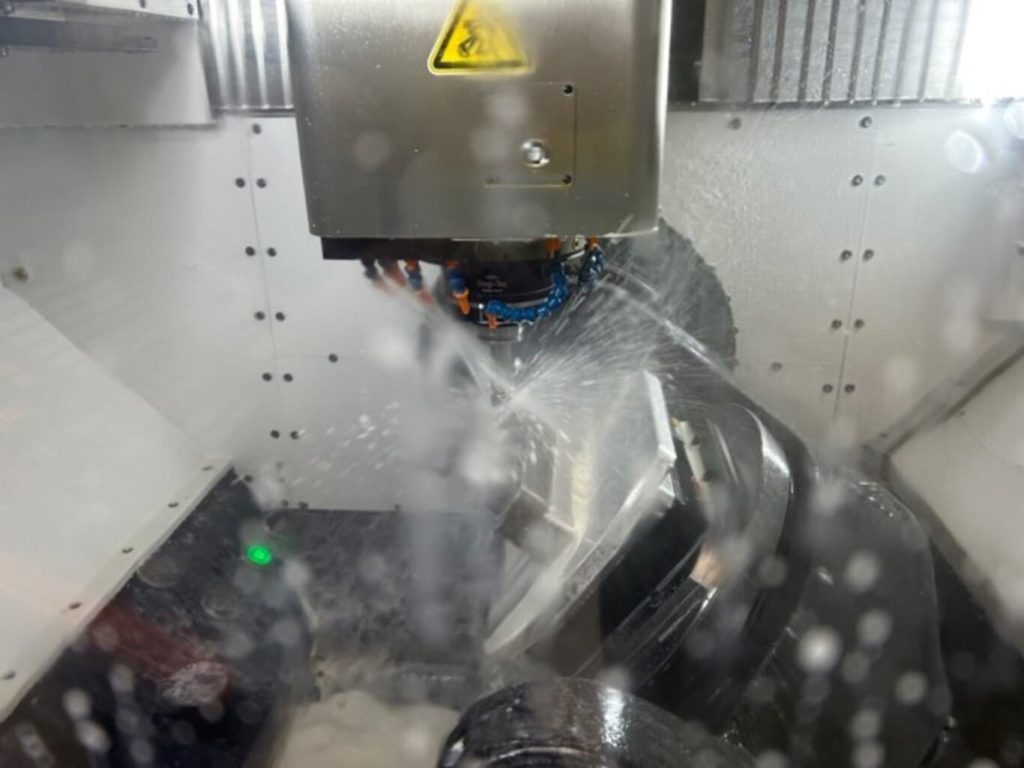

Contract manufacturing with 3 and 5-axis CNC manufacturing

Supported by our CAD department and the use of several CAM work places, our 3 and 5-axis machining centres have virtually no limits when it comes to machining. The highest precision requirements can be met with all commonly-used materials.

- Plastics

- Steel

- Aluminium

- Copper

- Brass

- Titanium

- Wood

Wire and sinker EDM contract manufacturing

Using our wire and die-sinking EDM machines, we create mould inserts for our mould making. High-precision contours can be produced without any problems:

- Electrodes

- Mould inserts

- Gauges

- Gear wheels

- or the smallest sheet metal parts

Grinding contract manufacturing

Our grinding department offers a variety of processing options and types of grinding. Even materials that are difficult to cut can be machined precisely.

Turning contract manufacturing

As a result of long-standing cooperation with companies specializing in CNC turning technology, we provide short delivery times even for challenging contours.

There is also capacity available for combined processing by turning plus milling.

4 reasons why you should work with us

35+ years experience

Certified

Powerful partners

High quality

- 35+ years experience

- Certified

- Powerful partner

- High quality

Your contact for your enquiry

Sebastian von Waldthausen

- Mon.-Fri. 7am - 4pm

Your contact for your enquiry

Sebastian von Waldthausen

- Mon.-Fri. 7am - 4pm